EXTENDING IMPACT EXTRUSION LIMITS

The conceivable is also feasible

From conceivable to feasible

The HECKLER Company Group has specialised in extruded components for several decades. In the traditional sense, this refers to screws, rivets, bolts, corrugation, bushing, etc.

However, we direct our focus at manufacturing symmetrical and asymmetrical, complex formed parts which are not conceivable as cold formed parts at an initial glance.

That is how we understand

“extension of the extrusion limits”!

Geometry – the conceivable is also feasible

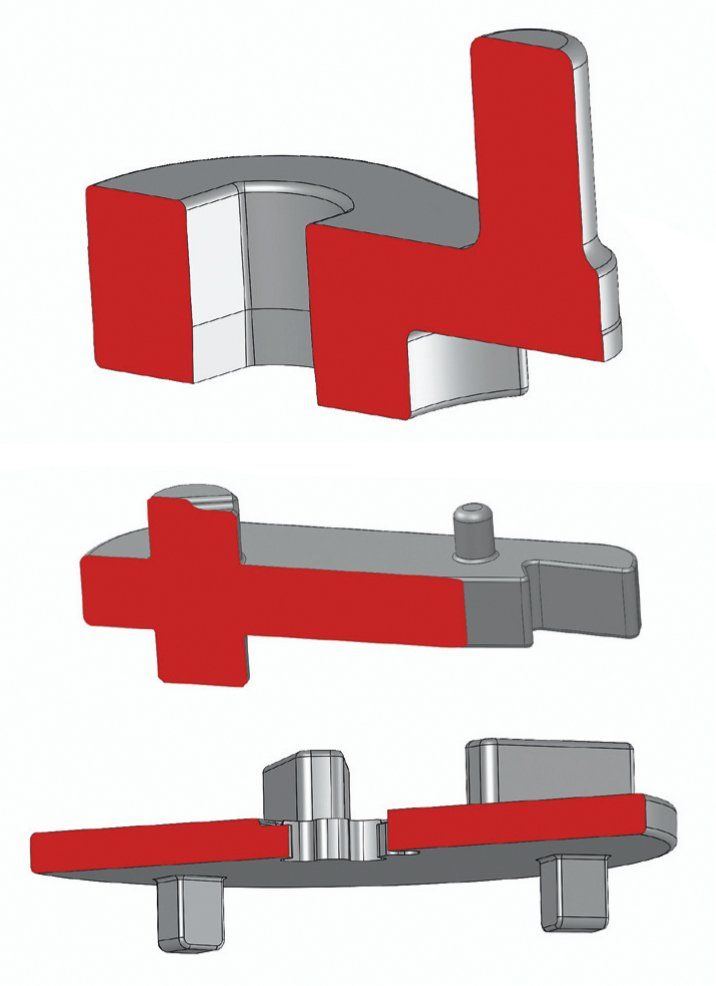

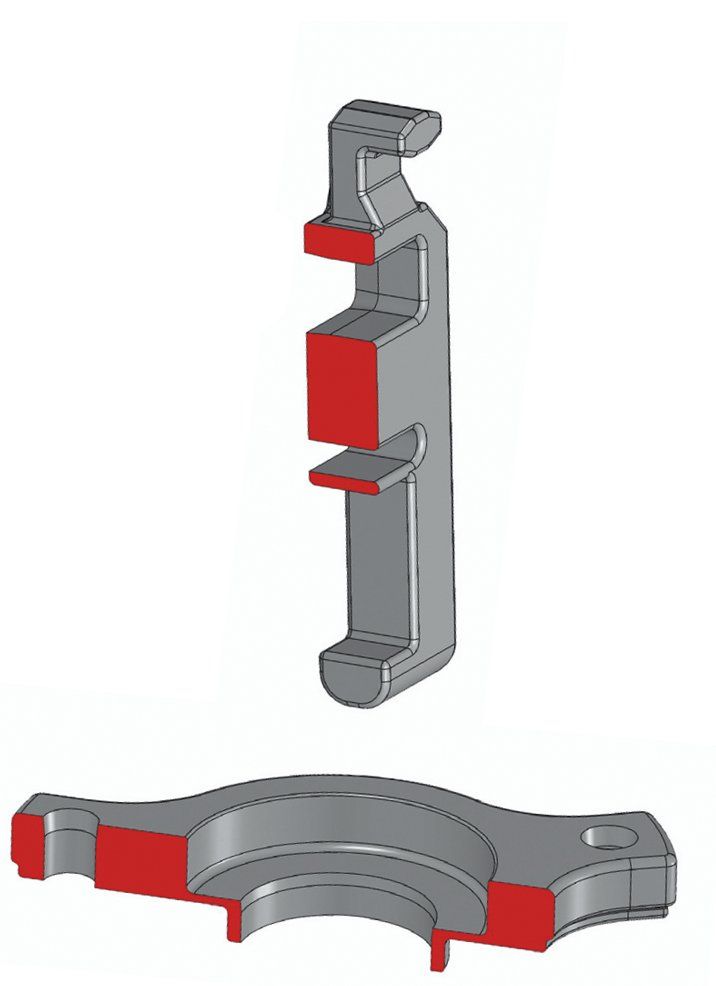

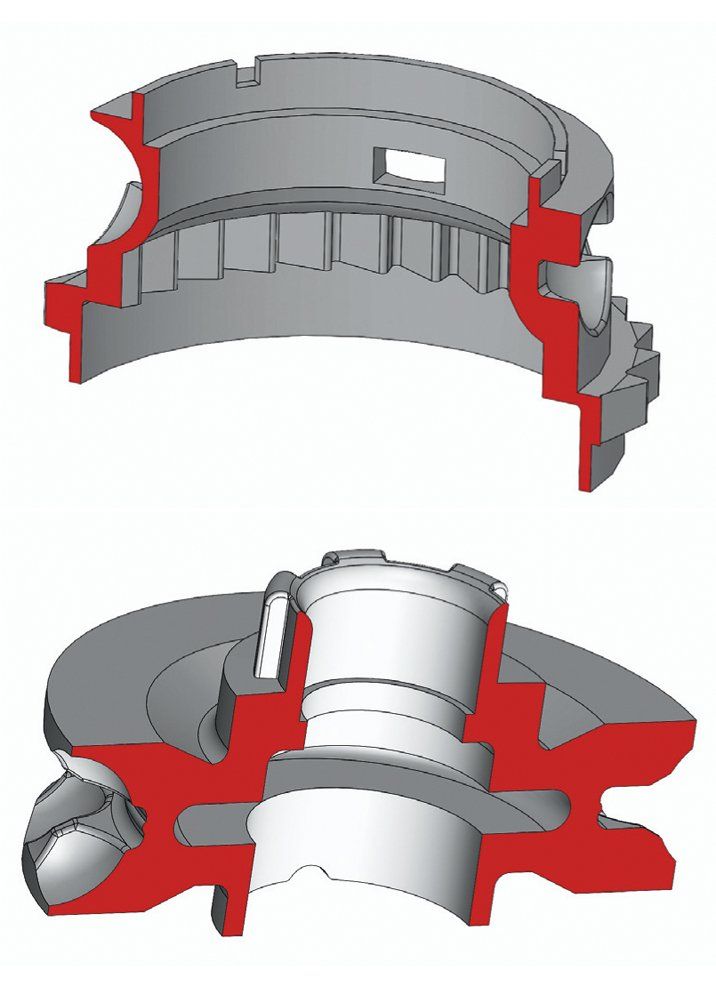

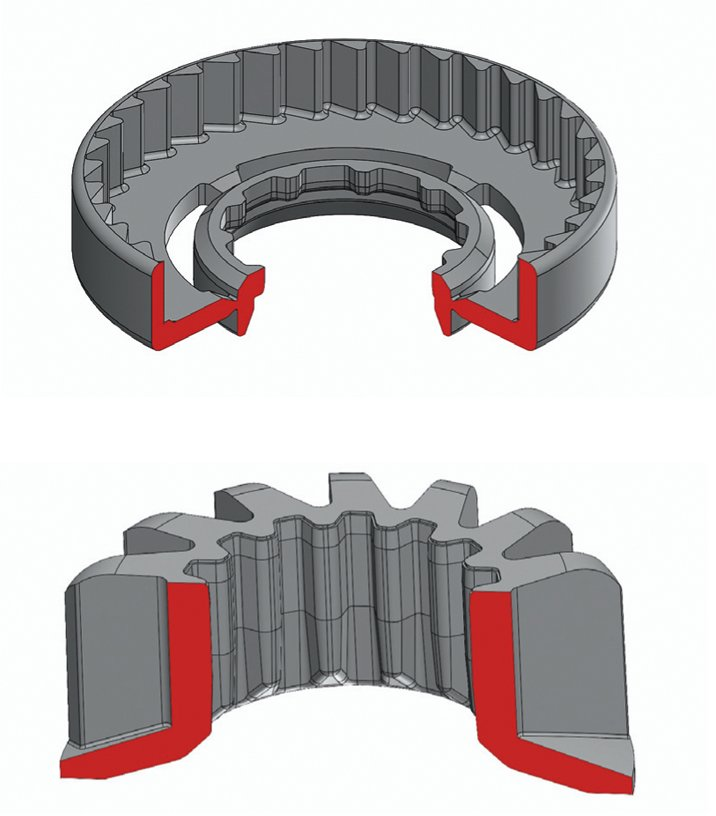

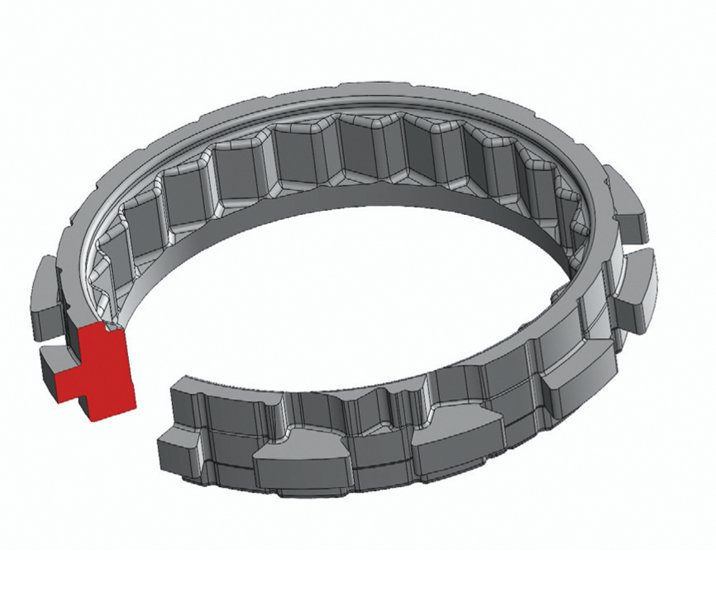

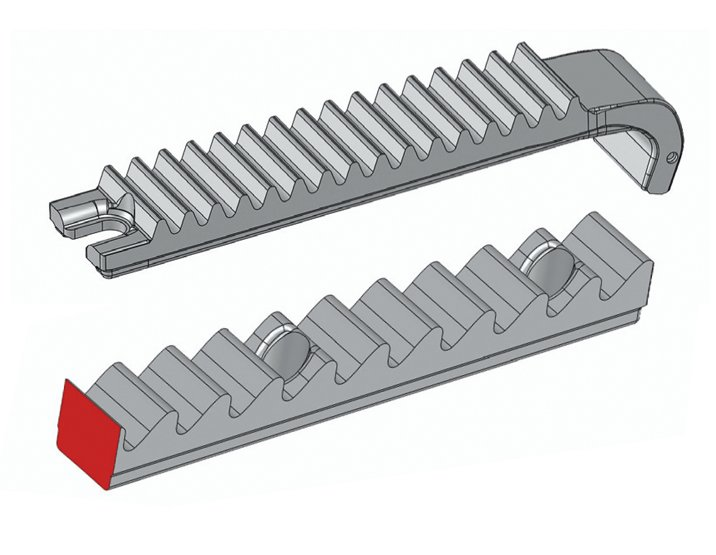

Information: Red areas mark cutting areas or component cuts

Solid bolts

- opposite, single-sided, asymmetrical

- representable without “transferral”

- idea possible as a single-part component group

Continuous gearing up to the tooth root surface

- high solidification due to hight natural strain

- solidification increase due to up to

< 25% cold work hardening in the gearing area